The material was first discovered, in a serendipitous manner, in the mid-80s, and my wife's old chem lab teacher became one of the Nobel laureates in 1996. Co-inventor Richard Smalley went to his grave studying its use in cancer, and the efforts to grow long tubes of Buckyball material — carbon nanotubes — has been frustrating.

But now the concept may finally come into its own through its inclusion in plastics, and in the area of solar energy.

Right now solar power systems are based on either silicon oxides, like chips, or some collection of rare earths, like cadmium. These are produced in large production facilities that create a lot of pollution.

But what if you could make solar cells, like you do cling wrap? What if you could coat every window, anywhere, with this wrap, and what if it were cheap enough to be used anywhere?

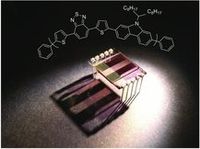

This “super plastic” is also known as an organic solar cell. What makes it organic is that it's a carbon molecule, based on C-60.

The scientific term for the compound is PCDTBT (poly [N-9′-heptadecanyl-2,7-carbazole-alt-5,5-(4′,7′-di- 2-thienyl- 2′,1′,3′-benzothiadiazole): PCBM ([6,6]- phenyl-C61-butyric acid methylester) or PCDTBT-PCBM. It's an outgrowth of “Buckyball” technology, first discovered by a Rice team which included my wife's chem lab teacher, Robert Curl. It's a hot area for patents.

Now a British team has tested the substance and reported they can not only be produced like Saran Wrap – spread over a surface and allowed to dry like a layer of varnish – but that they can naturally arrange themselves for high efficiency. The key to making them even more efficient — cleaning the equivalent of shellack off them.

The result could be a solar system that may not need mounting at all. That's important, because that's where the big costs in solar technology come from — making a device containing the solar material, then installing the material on a roof pointing toward the Sun. You need government approvals all along the way, there are huge distribution costs, and fossil fuel advocates use this to keep solar from taking off, even while they use government power to ignore the external costs of their own production.

In the British system it's the manufacturing method that is key. The materials themselves are already protected by patent. Once legal clearances are given, this material can go into production quite quickly, because we're not talking about a technology so much as an engineering methodology.

Other solar technologies could be obsolete within five years.